So, what’s left at the end of a lute making career?

Essentially the awareness that lutemakers were mostly good workmen, endowed with the practical mind that comes with it, as ingenious in solving problems as in using available materials.

And keen businessmen, with the same attitude shared by all entrepreneurs, well before terms like assembly line and capitalism were conceived.

Lutemaker, the workman

Children of a technological era, we expect the maniacal precision that wants to measure the universe in thousands of a millimiter while romanticising about the old masters creating top notch pieces from scratch, craftily turning only the best materials into masterpieces.

Well, modern times may have perfected assembly line processes, but economics always worked on the minimum investment maximum result principle. Otherwise it would be impossible to justify the presence of thousands of staves, counted by number by barrel or by crate, hundreds of fondi intagliati, carved soundboards, barrels of pegs and heaps of necks, small numbers of pretious lutes and hundreds of ordinary ones, all in one workshop (Lucas Maler’s inventory et al).

* What follows is not a picture exihibition, and the quality is what it is: to have a better look at details just double click on the pic for an easier to read enlargement.

Waste, what waste?

Now we may well assume that the instruments de pretio were really built the way we fancy today – and yet, not even precious instruments are necessarily unmarred:

while freewheeling cutting the zigzag margin of the parchment rosette, when the master run out of zig room s/he just filled the gap with ‘something’; and in the dot-and-diamond motive gracing the hole rim when s/he run out of dots (or room to fit them in) s/he filled the gaps in with black mastic; the rest of the guitar is the impeccable ebony and ivory frilly work we do indeed expect to find on a guitar by Tessler: who would have ever bothered to take notice of such irrelevant details 400 years ago?

while freewheeling cutting the zigzag margin of the parchment rosette, when the master run out of zig room s/he just filled the gap with ‘something’; and in the dot-and-diamond motive gracing the hole rim when s/he run out of dots (or room to fit them in) s/he filled the gaps in with black mastic; the rest of the guitar is the impeccable ebony and ivory frilly work we do indeed expect to find on a guitar by Tessler: who would have ever bothered to take notice of such irrelevant details 400 years ago?

here the strip layout was planned very carefully, for width and proportions, in order obtain the best aesthetical result; but then the top right maple strip includes a fat knot – master Anonymous must have had really no maple left – and the sides are disturbingly (to our eye, at least) mismatched where they would butt together.

But how about the ordinarii instruments, which we can safely assume being the bread and butter for most makers?

(And NO, this whole exercise is no plea for sloppy work!)

You don’t throw away, in any epoch, usable materials only because of some minor flaw, a knot or whatever, or a soundboard that just happens to be a bit narrow for the project, bookmatched or not even that, or any piece of hardwood that can be used for a fingerboard (see below, the r.h. pic with treble rider) or any veneering. It simply comes down to the maker’s ability to make the most of whatever is at hand.

On an ordinary instrument you are likely to find a fingerboard made of two pieces, not even of matching grain,

in Rome

as in Vienna (including one chunky knot).

In extreme cases even a whole lute body could be chopped up and reassembled after some shaving off, in order to reduce it to a desired size (as described in Mary Burwell’s lute book).

One emblematic case in point is the 13-course Jauch (1734) in Copenhagen, where Andreas Balthasar uses a batch of really mediocre cypress staves, put together as they come, a couple of them with big knots,

while the soundboard is built up with (at least) five pieces, partly cannibalising bits from an old renaissance lute – quite clearly from a renaissance lute, since a couple of pieces show clear traces of the original bridge, with width and tip marks typical of that period. Conveniently, the middle piece contains the original rosette too (but the rope motive on the bass side has been left out), a nuisance less for AB. Everything is skilfully put together, and the amorino head is a most exquisite carving, a quality you really wouldn’t expect to see on such an ordinary work.

The bottom line is, this is the most remarkable baroque sound machine I’ve ever bumped into.

(A similar example: the 11-course lute by Andreas Berr in Ptuj is made of very simple materials, the plainest, very fine grain maple shell, three-piece spruce soundboard, pegbox of three different woods, the fretsaw ebony back plate made up of two layers of veneer glued together. The lute was played a lot, suffered major damage and underwent a complex intervention that would have hardly been justified had it not been an excellent tool for making music).

A well practiced hand

So much of a maker’s work is easy flowing, matter-of-fact, even on high quality instruments, that minor flaws are simply taken into account.

Our master here (Magno Graill) on this 97 cm s.l. theorbo starts building the shell from the middle rib (we always do, of course), working with top quality shaded yew, and ends up with adding 19 ribs on one side and 20 on the other, only for some fastidious silly bugger to count them all 400 years later: it must be the only 40-rib shell in history, but there it is.

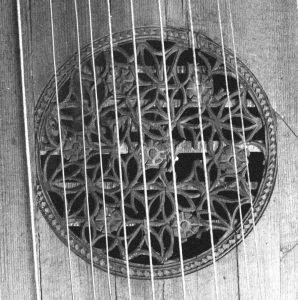

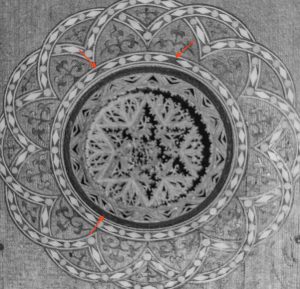

This rosette was obviously cut by a skilled hand, still it did not bother to avoid knife marks all around the edge (the kind of marks you leave inside, if at all, since that is the side where you normally cut your rosette).

This rosette was obviously cut by a skilled hand, still it did not bother to avoid knife marks all around the edge (the kind of marks you leave inside, if at all, since that is the side where you normally cut your rosette).

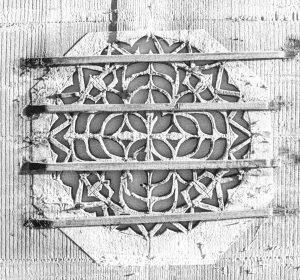

As we also see here, the bars reinforcing the weak open pattern were left in their natural colour and are aesthetically disturbing: we always stain them black today but the old masters never bothered.

This is what you’d be normally confronted with, a block print on a piece of paper glued inside the soundboard; in this case we see part of it because it comes from a theorbo, where the individual three roses are cut to a smaller diameter.

This is what you’d be normally confronted with, a block print on a piece of paper glued inside the soundboard; in this case we see part of it because it comes from a theorbo, where the individual three roses are cut to a smaller diameter.

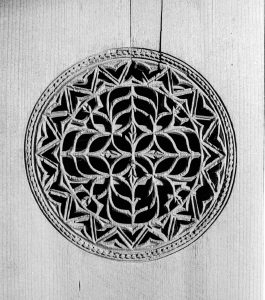

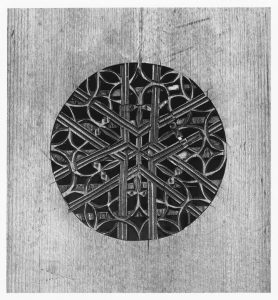

And here is a clear example of good cutting skills, where the craftsman didn’t even bother to glue a printed pattern onto the soundboard but only a reinforcing piece of paper: a few dry point circles with a compass and the rest is freehand cutting.

The scratched lines indicating bar positions were the common way to mark anything on the soundboard (the ‘pencil’ had already been invented, by the way, in mid-16th century in England, but did not hit the continent until the end of the 18th, and silver point was more expensive and less effective than any sharp point).

Indeed, inside the instruments you find all sorts of things, from ubiquitous glue splashes and squeeze-out to saw and toothing plane marks.

Where function leads the way

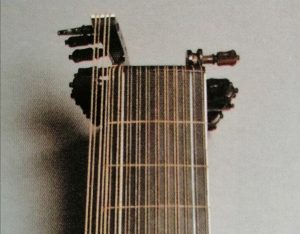

Clumsy as it may look, an oversized pegbox does the job and is more stable than the outleaning ‘bass rider’ under torque

Why bother carving a new bridge when you only want to add two courses?

A strap holder so disturbingly in the ‘wrong’ place is a standard little trick to make the instrument rotate forward, making it easier to hold

The back of the neck of italian baroque guitars generally has a fairly flat arc, whereas the sides are flat (making the cross section look like a trapezium with one bulgy side). (I personally find this shape quite comfy but I know a couple of players who disagree – fair enough). Now, the guitar neck is made up of two parts, the neck proper and the heel that joints it to the block, which you shape glued together first, then veneer separately before you glue them back together. The fact is that veneering a half round curve on that little bulgy triagular chunk of wood is a real pain in the neck and becomes much easier if you use a gentle curve plus flat ‘wings’.

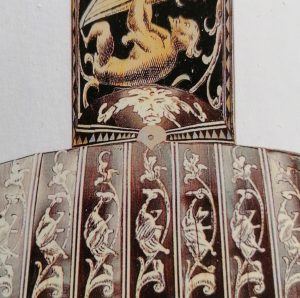

Makers adopted this solution throughout history, from Sellas to Stradivari, adding in the process a nice visual effect using decorative purflings

Isn’t it lovely?

A heart, more often a pike, is a common and quite pleasing aesthetical touch, but why slap it on a part of the instrument where it is least likely to be seen? The fact is that when you veneer the back of the extension this is the part that, due to its complex double curve, is most likely to crack open along the grain: the best way to patch it up is by cutting and inlaying a decorative element, the shaft of the pike meeting the purpose perfectly.

In some cases you’d do it anyway, ‘cos it looks nice, but generally you wouldn’t (and they didn’t). (Here, by the way, somebody thought it better to get rid of the original clumsy strap holder, in the believe that the original and functional hook looked uglier that the ugly patch – or simply didn’t think it was useful enough and didn’t bother with replacing the hook).

Wake up, you incurable romantic and

vivi lieto!